Using Technology to Streamline Safety Audits

In today’s world, technology has become an integral part of every industry. It is no surprise then that the safety audit process has benefited from the use of technology as well. Safety audits are a crucial part of any workplace, and using technology to streamline the process can help ensure that safety standards are met and maintained.

Safety audits are conducted to identify potential hazards in a workplace and to ensure that all safety regulations and guidelines are being followed. The purpose of these audits is to identify risks, assess their severity, and develop strategies for reducing or eliminating them. In order to do this efficiently and effectively, organizations must utilize the latest technology available in order to streamline the process of conducting a safety audit.

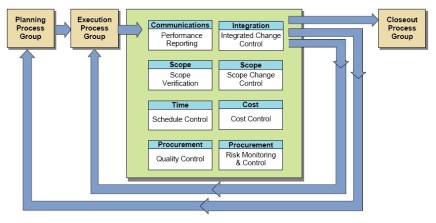

One way that organizations can use technology to streamline their safety audit process is by implementing automated data collection systems. Automated data collection systems allow organizations to quickly collect data from various sources such as sensors, machines, or personnel in order to create accurate records of any potential hazards or issues in the workplace. This data can then be analyzed by professionals in order to determine how best to address any issues identified during an audit.

Another way organizations can use technology when conducting a safety audit is through automation software programs, which allow them to quickly review documents related to occupational health and safety regulations and other relevant information. Automation software programs can also be used for generating reports on potential hazards or issues found during an audit so that they can be addressed as soon as possible without having to wait for manual reviews or paperwork processing time.

Technology also allows organizations to conduct remote audits using virtual reality (VR) headsets or 360-degree cameras mounted on drones for inspecting hard-to-reach areas without putting personnel at risk. VR headsets allow auditors virtually “walk” through an area before entering it physically while 360-degree cameras give auditors a better understanding of specific areas such as rooftops or hazardous locations by providing detailed images from various angles which can then be used for rectifying any identified risks immediately after completing an inspection remotely if necessary.

In addition, organizations may also make use of wearable devices such as smart glasses when conducting inspections which provide real-time feedback on employee activities while performing tasks related with hazardous materials or machines which helps reduce errors caused due human negligence while ensuring compliance with all applicable laws and regulations related with employee health and safety measures The feedback generated by these devices could also alert auditors immediately when something goes wrong so they can take corrective action right away instead waiting for reports after manual inspections have been completed making sure employees stay safe at all times during work hours

Technology has allowed us not only improve efficiency but also accuracy when it comes conducting audits since its implementation eliminates human error associated with manual reviews reducing time needed complete inspections significantly allowing companies focus more on taking corrective actions rather than spending time gathering information about potential risks associated with work place environment

Therefore when looking ways increase efficiency while still maintaining compliance with all applicable laws regulations companies should certainly consider utilizing latest technologies available today streamline entire process making sure their employees remain safe hazard free environment at all times

Exploring Modern Approaches to Auditing in Manufacturing

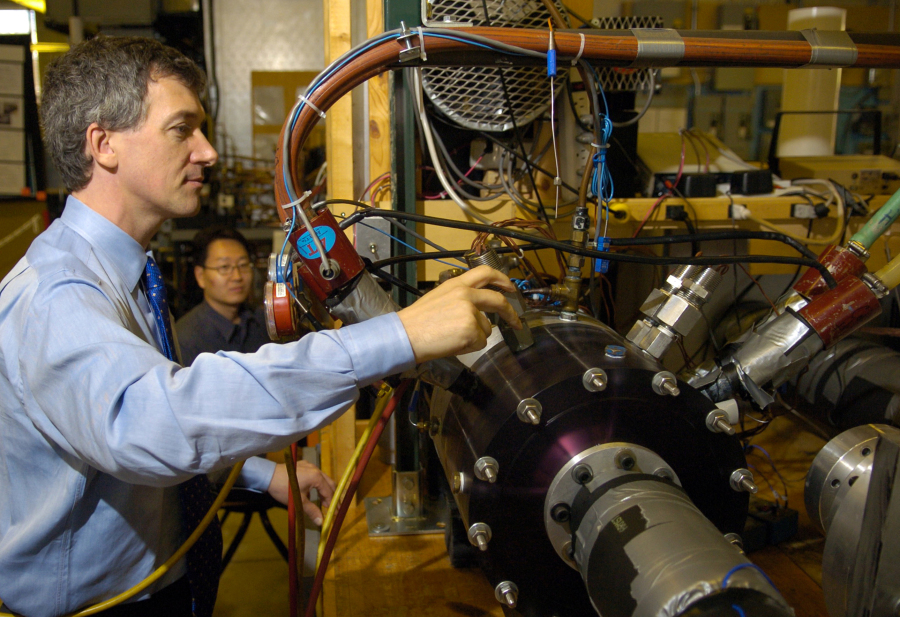

In the world of manufacturing, automation has become an invaluable tool. It helps streamline production processes and makes it easier to ensure quality standards are being met. However, while automation can help make production more efficient, it can also lead to potential problems if not properly monitored. That’s why harnessing the power of automation is essential when it comes to ensuring accuracy and compliance in the manufacturing process.

Auditing is a critical part of the manufacturing process, as it helps ensure that the end product meets customer requirements and industry standards. Traditionally, auditing has been done manually by a team of auditors who review documents and sample products for discrepancies or errors. This manual approach is time consuming and expensive and can sometimes lead to errors or omissions that could compromise product quality or safety.

Fortunately, modern approaches to auditing in manufacturing are making use of automated solutions such as robotics or machine learning algorithms that allow for faster and more efficient audits without sacrificing accuracy. Automated solutions can quickly analyze large volumes of data from multiple sources such as machines on the factory floor or sales data from customers in order to detect any anomalies that may indicate issues with product quality or compliance with regulations. In addition, automated solutions can be programmed to alert management when an issue arises so they can take swift corrective action if necessary.

Automation also makes it easier for manufacturers to monitor their processes over time in order to track progress towards goals such as increasing efficiency or reducing waste. Automated solutions allow companies to collect data on key performance indicators (KPIs) such as cycle times, defect rates, throughputs etc., giving them better insights into their operations which they can then use to identify areas where improvements need to be made in order to optimize their processes over time.

Furthermore, automated solutions like health and safety auditing software are helping manufacturers stay compliant with changing regulations in their industry by providing timely updates about new regulations that could affect their operations. This helps them avoid expensive penalties for non-compliance while also preventing potential safety hazards due to outdated systems or procedures not meeting current industry standards.

The benefits offered by automated auditing solutions are clear – they help streamline operations while ensuring accuracy and compliance with regulations which ultimately leads to improved customer satisfaction and increased profits for manufacturers using them properly . While these automated solutions do require some upfront investment in terms of hardware costs and programming fees , over time these investments will pay off through increased efficiency , improved quality assurance ,and better overall customer satisfaction .

In conclusion , harnessing the power of automation when it comesto auditingmanufacturing processes is essential for today’smanufacturers who want to understand how their processes are performing in the face of constantly changing regulations and industrystandards.

Automation allows for more efficient audits while ensuring accuracy and safety so that the end product meets the highest levels of qualityand compliance.

The long term benefits offered by automation solutions will far outweigh any initial investment required to make it work properly. For manufacturers looking to implement automated auditing solutions, there are a few factors to consider. The first is to identify what type of automation solution they need, as there are many different types available ranging from robotics to machine learning algorithms. Companies should also ensure that their chosen solutions are able to integrate with other existing systems and processes in order to minimize disruption and ensure maximum efficiency. Finally, it is important for them to have a clear understanding of the data they need in order to effectively monitor their operations and track KPIs over time.

The implementation of automated auditing solutions can also require some changes in organizational structure. This can include hiring more workers that specialize in managing technology, creating new roles dedicated solely to overseeing automated processes, or restructuring departments so that they can better manage the data generated by these solutions. While these changes may seem daunting at first, ultimately they will help companies get the most out of their automation investments by ensuring that the right people are in place to oversee and manage their new systems effectively.

At the end of the day, harnessing the power of automation when it comes to auditing manufacturing processes is essential for any company looking for an efficient way of ensuring accuracy and compliance with industry standards while optimizing their production processes over time. Automated solutions offer a wide range of benefits including faster audits with less effort, better insights into performance indicators such as cycle times and defect rates, improved quality assurance due to real-time updates on changing regulations, and greater customer satisfaction due to increased product reliability and safety standards being met. Investing in automated auditing solutions now will enable manufacturers reap long-term rewards later on down the line when it comes time for them assess how well their operations have been performing over time as they strive towards achieving success within their industry.